Aims Community College is celebrating Career and Technical Education Month this February.

Category

- Blog Post

Audience

- Alumni

- Faculty

- General Public

- Staff

- Students

Where Skills Meet Technology

From healthcare and skilled trades to advanced manufacturing, IT and public service, Aims designs programs to move students from the classroom to the workforce with purpose and momentum. Did you know nearly 60% of Aims Students are in Career and Technical Education (CTE) programs? Those students chose programs designed to build skills, earn industry credentials and step confidently into careers.

Aims offers more than 545 distinct CTE courses each year. To complement these programs, Aims invests in technology to supercharge experiential learning. Get to know some of the gear that prepares students for careers.

Electronic Window Into the Human Body

Students in Aims Allied Health and Emergency Medical Service programs get to learn about the human body in a way that feels futuristic thanks to the Anatomage Table. It is a giant touchscreen that lets you explore anatomy layer by layer, rotate organs in 3D, zoom into muscle groups and simulate real-life physiological processes without ever touching a scalpel. This digital cadaver lets students see how human body systems connect and interact.

Virtual Reality as a Learning Tool

Virtual reality (VR) uses immersive digital tools to simulate real-world environments. Aims students have opportunities to use training equipment that overlays digital information onto physical spaces, allowing students to practice procedures, visualize complex systems and learn safely.

One example is that several departments use a VR fire extinguisher program, which saves the cost of chemicals emitted by a physical fire extinguisher. Saving the expense of purchasing materials like paint and metal, so Automotive Collision and Refinishing students can practice painting a car with a VR car painting simulator. Students in the Master Automobile Service Technology and Fort ASSET programs can also learn to change oil in virtual reality.

Both Automotive and Welding students use a virtual reality welding simulator to hone their technique before stepping into a helmet and a welding booth. It replicates projects and tools to emulate what it feels like to weld with guns and torches with sparks, grinding and more. The program tracks and scores student proficiency and identifies what went well and what went wrong.

Sharper Skills Before the Road or Skies

Commercial Driver's License (CDL) simulator technology is part of the CDL program. Aims invested in a cutting-edge driving simulator that gives students realistic practice with shifting, urban and rural driving, bad weather and hazard scenarios before they ever climb into a real semi-truck. Instructors report that learners grasp core skills faster and with less stress. Once they gain confidence, they are better prepared to be behind the wheel of a semi truck.

Aviation is another department that uses computer-based simulations in education. Flight simulators prepare students for the cockpit. This resource is available to students outside of scheduled class time, giving them the freedom to practice independently and build muscle memory without the pressure of being in the air. To instill confidence, these systems can replicate emergencies and complex flight conditions. Simulators are also available for Air Traffic Control to mimic conditions in a control tower.

Technology That Mirrors the Real World of Work

The new Aircraft Maintenance Training Center (AMTC) is fully equipped with state-of-the-art technology and tools to help students learn about planes and the systems that power them. Aviation maintenance technician students use trainers and modules that replicate real aircraft environments. Through these trainers, students develop skills in safety wiring, flight control rigging, landing gear and brake systems, aircraft fluids, hydraulic systems and more. Environmental and safety-critical technologies are also emphasized, including air conditioning, oxygen systems and fire detection, preparing students to meet standards and transition confidently into real aircraft.

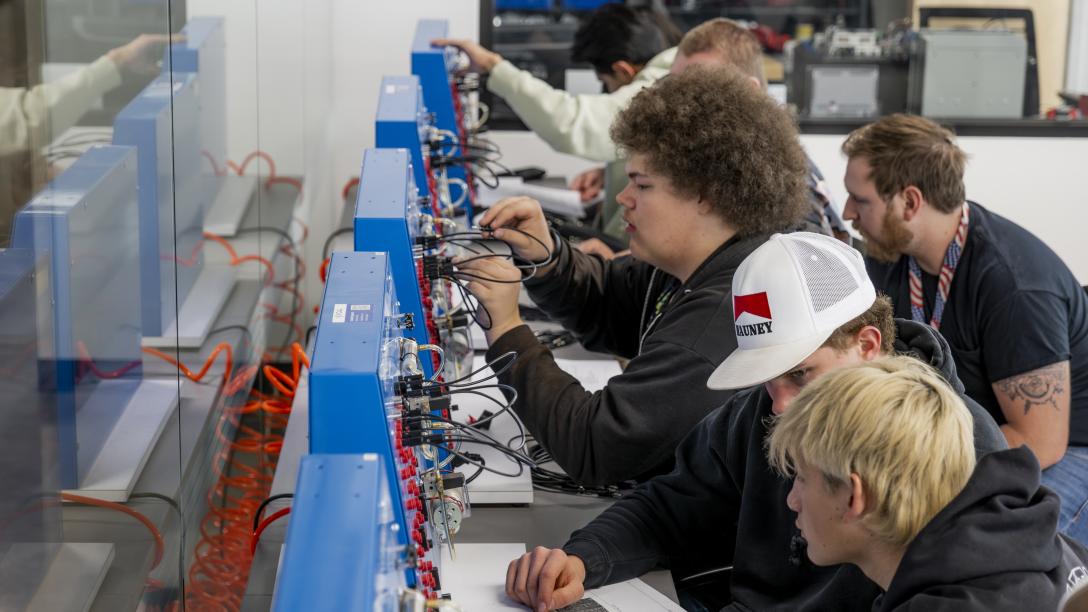

Other Aims: CTE programs utilize similar tech, like Automotive, where trainers have everything from intricate hybrid-car motor systems to windshield-wiper mechanics. Industrial Technology students can explore motors, robotics and electrical systems.

Public Safety Training Tech

Located on the Windsor Campus, Sim City is a four-building, four-way intersection designed to feel like the real world. With residential and commercial spaces, it supports hands-on learning. These facilities are also available to local and federal agencies for public safety training.

One of the buildings houses one of the largest training mazes in North America. It spans three levels and includes multiple built-in obstacles. It challenges Fire Science and Fire Academy students to complete numerous repetitions. Cadets wear blackout masks while instructors introduce noise, requiring participants to navigate by touch and spatial awareness while all in bunker gear.

Also at the Windsor Campus, there is a virtual range, a laser-based system to improve marksmanship, speed and skill development for students in Police Studies and the Peace Officer Academy. People can participate in shoot/don’t shoot scenarios. It enables instructors to create high-pressure situations in which participants must make split-second decisions, thereby helping them prepare for real-world responsibilities.

Create State-Of-The-Art Drones

The Unmanned Aircraft Systems (UAS) program puts students at the controls of cutting-edge technology and real-world opportunities. Housed in the Gateway Building on the Windsor Campus, the program’s design and fabrication labs provide students with hands-on experience creating, modifying and analyzing drones using advanced tools such as 3D printers, CNC routing, laser cutting, aerial data processing and more. Outside, there is a 5,400-square-foot outdoor flight line where learners can fly and test out their drones.

High-Tech Training for Early Childhood Educators

Aims is pushing the boundaries of experiential learning in Early Childhood Education with the introduction of a set of life-like robotic infant simulators that challenge students to respond to real-world childcare scenarios in a controlled setting. These advanced robots cry, need feeding and soothing, and even track whether the learner supports the infant’s head correctly. Students can practice skills like feeding, diapering and multitasking before stepping into an actual childcare environment. Instructors can simulate emergencies and multiple infants needing care at once. The software logs and assesses student responses. This high-tech tool deepens understanding of the demands of early childhood work while strengthening confidence and competence for careers in education.

At Aims, theory accelerates into action. The technology behind these programs sharpens skills, builds confidence and shortens the distance between training and impact. Explore all Aims programs and discover what’s possible as a maker, builder and innovator.